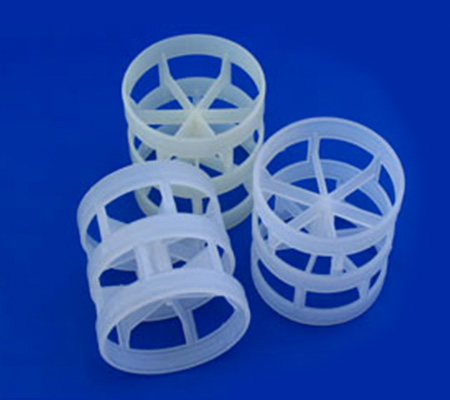

FP-Pall Ring

Pall rings were developed by BASF AG around 1940’s based on the raschig ring. They

are still widely used in the industry owing to their good capacity characteristics at low-

pressure drops. Punched windows on the outside facilitate better vapour flow and

increase capacity as compared to raschig rings.

Key Characteristics

- FP-Pall ping is the industry recognised pall ring equivalent

- High liquid hold up and residence time

- High mechanical strength

- Lower sensitivity to liquid and vapour distributor quality allows use with conventional

distributors

FP-Pall Ring Applications

- Gas treatment systems

- Chlorine drying

- Absorption and scrubbing services

- Stripping services

- Waste water treatment

- Chemical reaction absorbers

|

Size

|

Nos. / Cu.m.

|

Surface Area (m²/m³)

|

Void Fraction%

|

Packing Factor (F)

|

|

16 mm

|

210,000

|

338

|

88

|

95

|

|

19 mm

|

100,000

|

240

|

88

|

68

|

|

25 mm

|

51,000

|

210

|

89

|

52

|

|

38 mm

|

13,500

|

135

|

90

|

32

|

|

50 mm

|

6,500

|

100

|

92

|

25

|

|

75 mm

|

1,820

|

92

|

93

|

20

|

|

90 mm

|

1,200

|

85

|

93

|

16

|

Material of construction (MOC)

- Polypropylene (PP)

- Polyvinylidene fluoride (PVDF)

- Polyvinyl chloride (PVC)

- Perfluoroether (PVA)

- Chlorinated polyvinyl chloride (CPVC)